Sheet and plate tapping gets flexible

- Dec 10, 2018

- 1 min read

Tapping isn’t just for the drill press operator anymore.

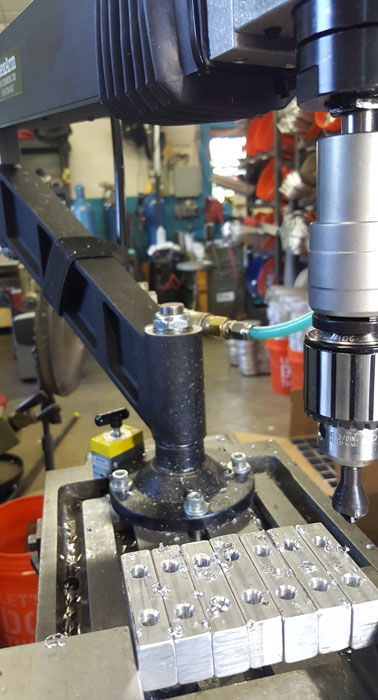

Tapping, historically done with a knee mill or drill press in most sheet metal shops, has morphed into one of the most flexible operations on the plant floor. Portable tapping arms go where the work is; hydraulic tapping tackles the bigger tapping requirements; and flexible robotics can change taps automatically in seconds.

Although technology has certainly changed, some aspects of tapping have not. The need for good tap organization is still as vital today as it ever was. Most shops sort taps by size and style: coarse, fine, form, etc. However taps are sorted, a shop needs a system that makes sense so that workers can quickly and efficiently find the tap sizes they need. Time is money, and downtime looking through disorganized taps is wasted money. The 5S concept applies to tap organization.

Job documentation still plays a critical role as well. Every fabricator needs clearly marked drawings that detail materials of construction, hole and tap sizes, dimensions, next steps, and more.

What has changed? Just about everything else.

Comments