The price of using the wrong tool

- Lindsay Eilerman

- Jul 26, 2017

- 2 min read

You wouldn't use a hammer to drive a screw, and you shouldn't use a CNC machine to tap a hole. Sure, technically it can get the job done... but you'll probably damage the screw, your part, and possibly yourself.

We recently had an experience in the shop, with someone who was new and not yet quite experienced enough to choose the right tool.

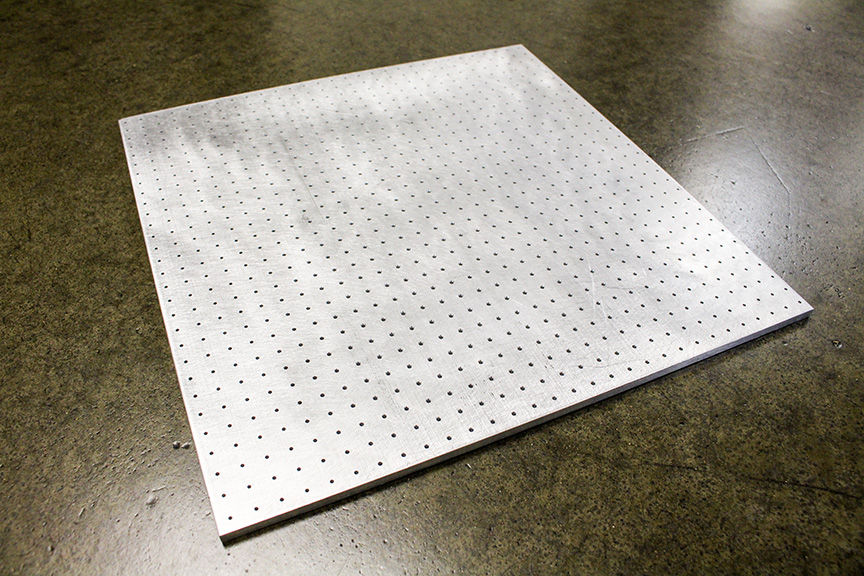

The project was simple, yet tricky; an aluminum plate 12" x 12" x .25" that required 900 tiny tapped holes (.067"), barely larger in diameter then a standard paperclip.

So, using our new 5 axis machining center, he located and spot drilled 900 holes. Then went back and drilled all 900 tiny holes.

Then the machine switched tools and began to tap. One hole. Two holes. Three ho-SNAP! Broken tap. We drilled this part 1800 times on the CNC with no problem.

Then just three holes into tapping it and the part went sailing into the scrap bin. Five minutes later, a second part was scrapped with another broken tap.

A CNC machine, on average breaks 1 tap every 300 holes. A tap lasts 10 x longer in a FlexArm then in a CNC machine, breaking maybe 1 tap in 3000 holes. Our smallest arm, the A32, almost never breaks a tap when used correctly, and taps holes as small as #000.

And now, you can save even more on tooling with a FlexArm. Get $100 in Free Taps from OSG with the purchase of any FlexArm Tapping Arm.

Don't let parts on the scrap pile get you down. The A-32 starts at less then $3000 and pays for itself within the first few jobs.

Comments